Zhimo Precision Ceramic

As a member of Root Group, With 10 years development, Zhimo New Material has already set up independent R&D center and owned new manufacturing base with annual output 3000Tons. Based on the extraordinary R&D ability and high-quality production control, Zhimo is leading the development of Chinese ceramic grinding media industry. In R&D area, Zhimo has cooperated with Jingdezhen Ceramic Institute and National Engineering Research Center for Domestic & Building Ceramic and has successfully completed the research of 0.1mm and 0.05mm beads and put into trail production. In Zhimo Anhui Production Base, from Forming, Sintering, Polishing, Selecting to Sieving, Zhimo strictly controls each production process to ensure the high-quality product.

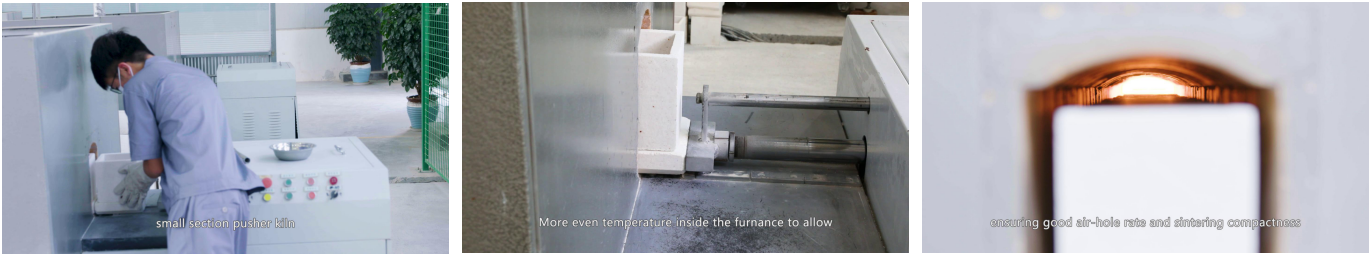

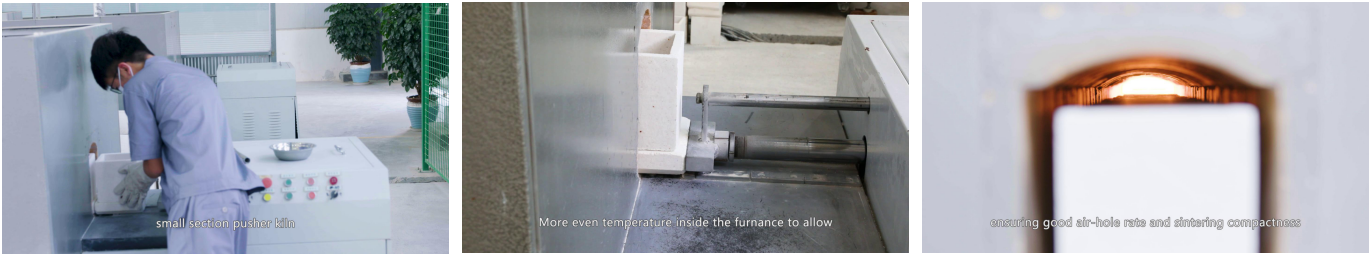

Sintering Furnance

Self-owned IIPR sintering quipment performs with continuous, small section pusher kiln. More even temperature inside the furnance to allow the same heat radiation on each bead in the same thermodynamics environment, ensuring good air-hole rate and sintering compactness.

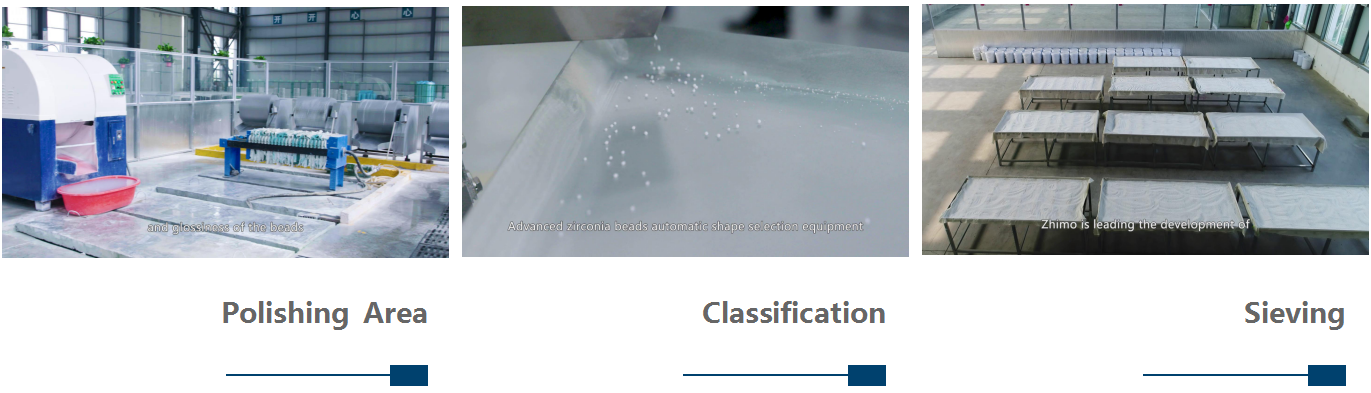

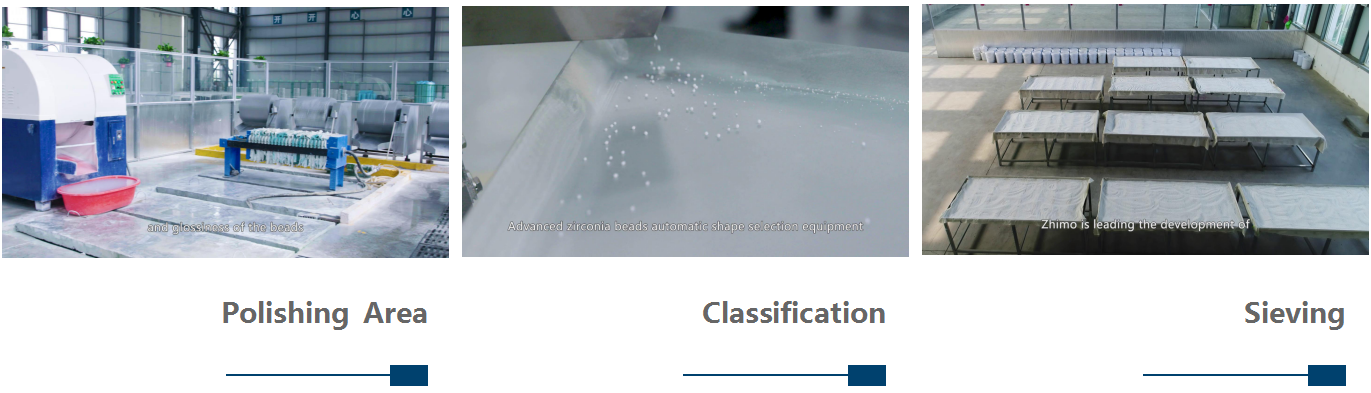

Multiple sets of polishing machines to enhance the smoothness and glossiness of the beads. Advanced zirconia beads automatic shape selection equipment ensures sphericity of all beads bigger than 99%, strictly controlling the percentage of admixture.

Random sampling before dispatching. Density test of each batch beads with electronic density scale. Use strength test equipment and planetary ball mill to guarantee the strength and high-wear resistant property of each batch products.

For each month, each furnance can give out 8 tons of beads. Monthly productivity is 32Ton. The normal size range is 0.1-5mm. For these size, Zhimo usually will have in stock.

Root Anhui Manufacturing Base

Root Anhui New Manufacturing Center is the manufacturing base for Root Group. We have set up 4 production lines inside the manufacturing base for zirconia parts and grinding media. Deep in technology research, win in high-quality control. Zhimo will always hold the concept of Quality Supreme, Service First to provide all customers with high quality ceramic grinding media.

Zirconia Beads Workshop

Sintering Furnance

Self-owned IIPR sintering quipment performs with continuous, small section pusher kiln. More even temperature inside the furnance to allow the same heat radiation on each bead in the same thermodynamics environment, ensuring good air-hole rate and sintering compactness.

Multiple sets of polishing machines to enhance the smoothness and glossiness of the beads. Advanced zirconia beads automatic shape selection equipment ensures sphericity of all beads bigger than 99%, strictly controlling the percentage of admixture.

Random sampling before dispatching. Density test of each batch beads with electronic density scale. Use strength test equipment and planetary ball mill to guarantee the strength and high-wear resistant property of each batch products.

For each month, each furnance can give out 8 tons of beads. Monthly productivity is 32Ton. The normal size range is 0.1-5mm. For these size, Zhimo usually will have in stock.