The Application of Zirconia in the Field of Structural Ceramics and Functional Ceramics

- 2020-11-10 10:49-

Zirconia is an inorganic non-metallic material with high temperature resistance, corrosion resistance and wear resistance. Since the mid-1970s, developed countries in the world have invested heavily in the research and development of zirconia series products, expanding the application field of zirconia to structures Materials and functional materials, and zirconia is also one of the high-performance new materials that are mainly encouraged in the national industrial policy. It is currently being widely used in various industries.

1. The application of zirconia in the field of structural ceramics

In 1975, Australian R.G. Garvie made partially stabilized zirconia using calcium oxide as a stabilizer, and for the first time improved the toughness and strength of zirconia, greatly expanding its application in the field of structural ceramics.

01 Zirconium Oxide Ceramic Bearing

Zirconia all-ceramic bearings have the characteristics of wear resistance, corrosion resistance, high temperature resistance, high cold resistance, oil-free self-lubrication, and anti-magnetic and electrical insulation. They can be used in extremely harsh environments and special working conditions.

At present, zirconia ceramic bearings have been adopted by miniature cooling fans, and their product life and noise stability are better than traditional ball and sliding bearing systems. Foxconn is the first to adopt zirconia ceramic bearings on computer cooling fans.

02 Zirconia Ceramic Valve

At present, the valves commonly used in various industries in our country are metal materials. Due to the limitation of the metal materials themselves, the corrosion damage of the metal has a considerable impact on the life span, reliability and service life of the valve wear resistance.

For valves, the climatic conditions of their pipelines are complicated; the appearance of hydrogen sulfide, carbon dioxide and certain organic acids in oil, natural gas and oil layer water, etc., increase the destructive power of the surface and quickly lose the ability to work.

Zirconia ceramic valves have excellent wear resistance, corrosion resistance, high temperature resistance, and thermal shock resistance, which can be competent in this field.

03 Zirconia Abrasive Material

Zirconia grinding balls have high hardness, low wear rate and long service life, which can greatly reduce the pollution of grinding raw materials and ensure the quality of products. At the same time, the density of zirconia material is high, and the impact energy is strong when used as a grinding medium, which can greatly increase Grinding and dispersion efficiency.

Good chemical stability determines its corrosion resistance and can be used in acidic and alkaline media. The zirconia ceramic grinding ball developed by the China Building Materials Science Research Institute has a wear rate of only 0.04/24h, and is widely used as a grinding medium in mills such as ball mills, vibration mills, and stirring mills.

2.the application of zirconia in the field of functional ceramics

01 Zirconium Oxide Ceramic Ball for Ballpoint Pen

In general, the balls for ballpoint pens are mainly stainless steel and tungsten carbide materials. However, these types of balls often appear broken, dropped, and dead during the writing process. At present, it is produced by Hebei Yonglong Bangda New Material Co., Ltd. The "Zirconium Oxide Ceramic Ball for Ballpoint Pen" jointly developed with the State Key Laboratory of New Ceramics and Technology of Tsinghua University overcomes the above shortcomings and fills the gaps in the country. This scientific and technological achievement has been listed as a national pen industry "Eleventh Five-Year" country Focus on promoting new products.

02 Zirconium Oxide Ceramic Tool

Zirconia ceramic knives have the characteristics of high strength, wear resistance, no rust, no oxidation, acid and alkali resistance, anti-static, and no reaction with food. At the same time, the knife body is shiny like jade, which is an ideal high-tech green tool. At present, the main products on the market include: zirconia ceramic table knives, scissors, razors, scalpels, etc., which have become popular in Europe, America, Japan and other places in recent years.

03 Zirconium oxide high temperature heating element

Zirconia is an insulating material at room temperature, its specific resistance is as high as 1015Ω·cm, it can conduct electricity when the temperature rises to 600°C, and it is a good conductor when the temperature is above 1000°C, it can be used as a high temperature heating element at 1800°C, and the maximum operating temperature can reach 2400°C , Has been successfully used in heating elements and equipment in an oxidizing atmosphere above 2000 ℃.

04 Zirconium Oxide Bioceramic Material

The quality of the porcelain tooth material directly affects its quality and the health of the patient. Because the inner crown of the porcelain tooth is made of different metal materials, the metal inner crown is easy to oxidize with the oral saliva, and the zirconia material is baked. Because porcelain teeth do not have a metal inner crown layer, the teeth have good transparency and excellent gloss, and effectively avoid the problems of tooth hypersensitivity and dark gum lines. It has a good enough shading ability and can perfectly solve the patient's dental cosmetic needs.

The strength of zirconia material makes up for the shortcomings of ordinary porcelain teeth that are easy to bounce. It has good biocompatibility, does not stimulate the oral mucosa tissue, and is easy to clean. It is currently the best quality porcelain teeth at home and abroad, and it can be called a porcelain tooth family. The nobility in.

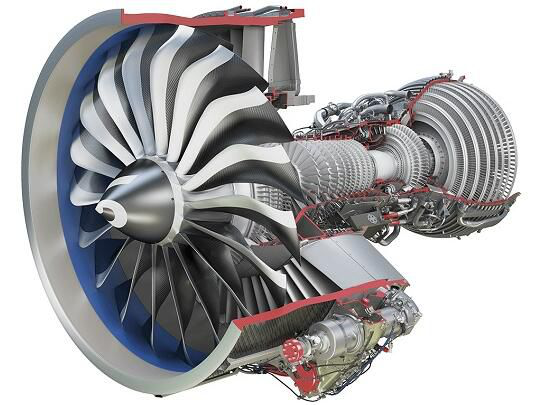

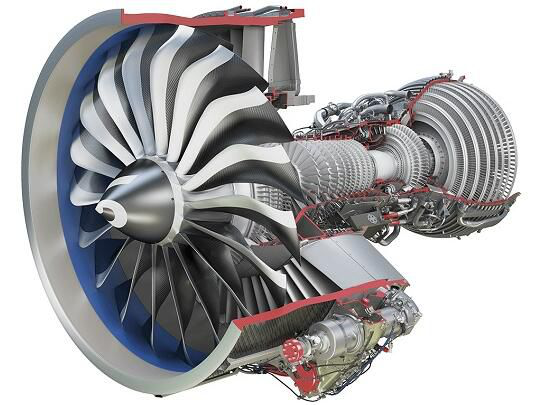

05 Zirconium oxide coating material

High-performance Y2O3 and other stabilizer stabilized zirconia thermal barrier ceramic coating materials are mainly used in high-performance turbine aeroengines. Thermal barrier coatings use ceramic heat insulation and corrosion resistance to protect metal materials, which can not only improve fuel combustion efficiency, but also greatly extend the life of the engine. It is used in aviation, aerospace, marine ships, large thermal power generation and automotive power It has important application value and is one of the important technologies in the field of modern defense cutting-edge technology.

06 Zirconium Oxide Communication Material

In recent years, with the development of emerging industries such as information and communications, its products are increasingly developing in the direction of high precision and miniaturization. The excellent mechanical properties, corrosion resistance and high insulation properties of toughened zirconia ceramics can be competent in this field. Zirconium oxide ceramic pins and zirconia ceramic sleeve products have come out.

07 Zirconia Oxygen Sensor

In the automobile industry, oxygen sensors are indispensable for engines that use three-way catalytic converters to reduce emission pollution. Currently, there are two types of oxygen sensors in use, titanium oxide and zirconia, of which the most used is zirconia oxygen. sensor. Japanese scientists made zirconia into a porous oxygen sensor, installed in the engine to automatically detect the ratio of oxygen to combustion gas in the engine, and automatically control the ratio of input gas and exhaust gas, thereby greatly reducing the harmful gas emitted by the car.

Previous:Previous:How Much Influence Does the Selection of Zirconia Beads Have on Grinding?

Next: Next:What are the Elastic Deformation Characteristics of Zirconia Ceramics?

Related News