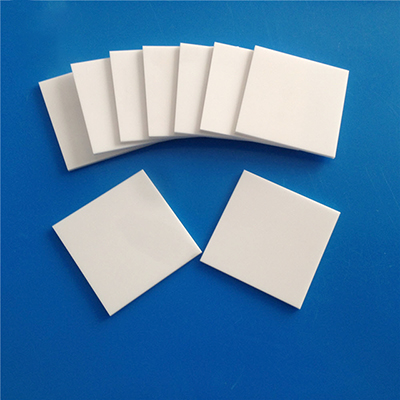

Ceramic Substrates are used in many electronic applications where a thin insulating layer of thermally stable material is required to conduct heat away from electronic components whilst electrically insulating them, and material is 96% alumina, zirconia, silicon nitride and aluminum nitride, All our substrates are produced by laser cutting and surface grinding. Properties with excellent insulation, high mechanical strength, high thermal conductivity, low expansion coefficient, small dielectric constant, high-temperature resistance, excellent erosion and wear resistance, good quality in chemical shock heat and cold.

Substrates – Manufacturing and processing services:

Laser precise cutting, drilling, and scribing.

Cutting the highest accuracy: + / - 0.02mm

Cutting maximum size: 152.4 * 152.4 mm

Cutting minimum aperture diameter: 0.1 mm

Cutting max thickness: 1.5 mm

Laser marking Ceramic Substrates. Precise Surface grinding. Surface polishing.

We provide plates to standard sizes or according to your drawings: Standard sizes of substrate/plates available in Stock:

| 96% Alumina | White Zirconia | Black Zirconia | Si3N4 |

| 60*70*0.2mm | 100*100*1mm | 100*100*0.8mm | 100*100*0.5mm |

| 62*62*0.28mm | 100*100*2mm | 100*100*1mm | 100*100*0.8mm |

| 127*127*0.5mm | 100*100*3mm | 100*100*3mm | 100*100*1mm |

| 114*114*0.635mm | 100*100*5mm | 100*100*5mm | |

| 101*101*0.8mm | 100*100*10mm | ||

| 101*101*1mm | 150*150*4mm | ||

| 101*101*1.5mm | 150*150*6mm | ||

| 127*127*2mm | 150*150*8mm |

Any size can be customized according to the drawing

All kind of OEM ceramic parts

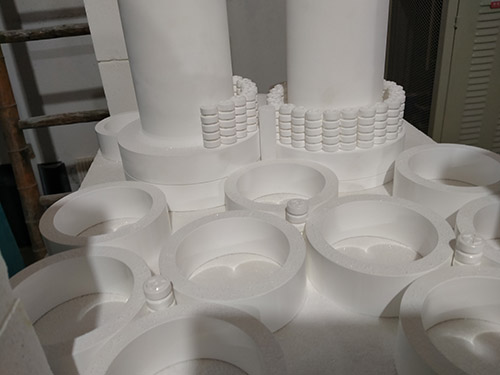

Production Pictures

Moulds

Pressing

Sintering

Parts processing

Previous:96% alumina ceramic sheet for electronic board Next:96% Alumina ceramic insulation plate with hole