Zirconium oxide ceramics are white, yellow or gray when containing impurities, and generally contain HfO 2, which is not easily separated. Pure ZrO2 has three crystal states under normal pressure. The production of zirconia ceramics requires the preparation of high-purity, good dispersion properties, ultra-fine particles, narrow particle size distribution, zirconia ultrafine powder preparation methods, zirconia purification mainly chlorination and thermal decomposition, alkali metal Oxidative decomposition method, lime melting method, plasma arc method, precipitation method, colloid method, hydrolysis method, spray pyrolysis etc.

In terms of structural ceramics, zirconia ceramics are widely used in the field of structural ceramics because of their high toughness, high flexural strength and high wear resistance, excellent thermal insulation properties, and thermal expansion coefficient close to that of steel. Mainly: Y-TZP grinding ball, dispersion and grinding media, nozzle, ball valve ball seat, zirconia mold, micro fan shaft, fiber pin, fiber sleeve, wire drawing die and cutting tool, wear-resistant tool, clothing button, Cases and straps, bracelets and pendants, ball bearings, golf ball hitters and other room temperature wear-resistant components.

All kind of OEM ceramic parts

Production Pictures

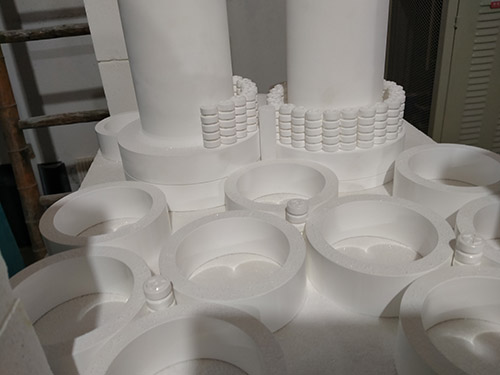

Moulds

Pressing

Sintering

Parts processing

Previous:Pump precision yttria stabilized zirconia ceramic plunger piston Next:Black zirconia zirconium oxide ceramics part