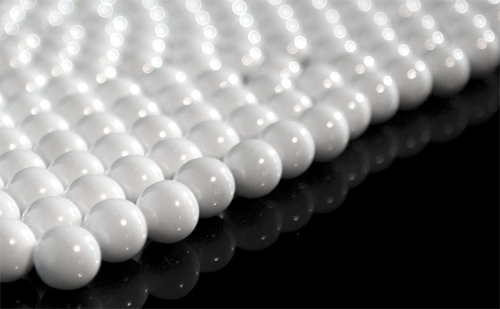

1. The filling volume of beads should not exceed the upper limit (85%);

2. Try to use beads with uniform particle size;

3. Choose suitable density beads for different viscosities;

4. Do not mix beads of different materials;

5. Beads of different materials are used for sand mills with different line speeds;

6. Keep a low speed when cleaning the sand mill with beads; use jog for mechanical speed regulation, and use low-speed zone for stepless speed regulation (recommended shaft speed is less than 1000rpm);

7. Regularly sift out old beads smaller than the lower limit;

8. Regularly check whether there are cracks or grooves in the positions of the sand mill separation device, the discharge end cover and the dispersion shaft for the existence of stress concentration areas such as cracks or grooves.

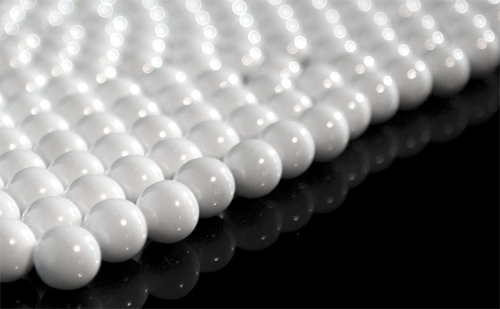

Instructions for use of zirconia beads:

1. According to the viscosity, hardness, dispersed particle size and grinding requirements of the grinding material, select the corresponding variety, specification and quantity of zirconia beads;

2. Put the material to be ground into the barrel of the grinder first, then put in an appropriate amount of zirconium beads, and then gradually add the zirconium beads after the grinder runs. The filling volume is generally 70%-85% of the internal volume of the grinder barrel;

3. Before grinding, clean the zirconium beads and the inner wall of the grinding machine barrel;

4. Do not allow the zirconium beads to run for a long time when the grinder is short of materials, otherwise the grinder is easily damaged;

5. After the grinding machine has been running for a period of time, the zirconium beads should be replenished appropriately to ensure the quality and efficiency of grinding.